BORONTECH Composite,omium Carbide alloy overlaid steel plates are highly resistant against wear and abrasion with moderete impact.

PROPERITIES OF BORONTECH ALLOY S

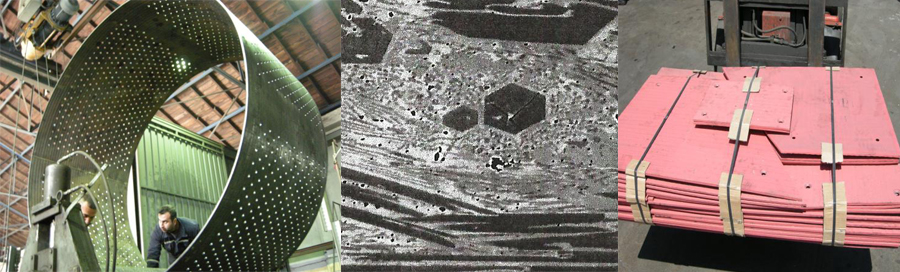

The alloy of hardfacing is iron-omium-carbon-manganese overlaid on Mild Steel plate.Carbides of omium(Cr,Fe)7C3,and carbides of boron distributed in the matrix of iron & omium.In some Borontech alloys the matrix is modified with Molibdenum,Niobyium , and Tungsten. Most commonly Borontech alloys containing approximately one-third of omium with 3- 4% of complex carbon. The undiluted,unwelded metalic mixture is containing 5 % C,35%Cr,1,5%Mn.Fe,Cr,C ,B alloys are used in severe conditions, where there is extreme erosion ,and therefore abrasion resistance is necessary

BORONTECH plate’s exceptional abrasive ,and erosive wear resistance, results primarily from their high volume fraction of hard carbides,though the toughness of the matrix also contributes to the wear resistance.

Fe-Cr-C alloy microstuructures have shown that,these type alloys have hypoeutectic,eutectic,and hypereutectic structures.M7C3 primary carbides form in large amounts at these Carbon concentrations.The extremely hard M7C3(1600HV) is surrounded by austenite,forming cracks at the interface of M7C3 and austenite.

BORONTECH CrB Wear Plate hardness is 52-57 RC average for single layer, where the hardness of Heat Resistant BORONTECH MoB , BORONTECH NbMoB , and BORONTECH W-ULTRA Alloy Plates can reach up to 64-66 RC at elevated temperatures.

The typical as weld chemical compositions of BORONTECH alloys are given below:

Elements(wt%) Cr C Mo Nb Si Mn B HRC(Single Lay.) HRC(Doub.Lay.)

BORONTECH CrB 24-28 3,5-4,5 - - 1,0 0,5 0,4 52-56 55-59

BORONTECH Mn 24-28 3,5-4,5 - - 1,4 2,4 0,4 50-55 54-58

BORONTECH MoB 24-28 3,5-4,5 1,0 0,3 1,2 0,5 0,6 55-59 58-62

BORONTECH NbMoB 26-32 3,5-4,5 0,5 1,2 0,8 0,5 0,8 57-61 60-64

.jpg)

BORONTECH Composite Alloy steel plate also available on ST 42,ST 52 , H2,316,307 , and 310 grade steels. Production of engineered shapes from BORONTECH Plates ,laser,and plasma cut pieces ,bends,pipes, flanges, and elbows, fan blades,vanes etc.also being made in our workshop with high precission.

MACHINING,CUTTING & WELDING OF BORONTECH PLATES

The composition,and hardnes of BORONTECH plate is not suitable for machining,and cutting with conventional methods.The high omium contetnt of alloy is not compatible with the use of oxy-flame cutting process.Edges and surface can be ground with abrasive disk.Plasma-arc, and laser is the most prefered method for cutting. Welding of ST 37-42 -52 side of the plate ,is possible with using basic manual electrodes.The hardfaced side is weldable with similar omium carbide type manual electrodes or tubular wires.

INDUSTRIAL APPLICATIONS

BORONTECH hard plates widely used in cement industry,power plants,steel industry,mining,glass industry,earth moving, oil industry,paper industry ,hydro-pulper liners,for wear protection of hopers,chutes,chute liners,fan blades,screw conveyors,conveyor liners,tube liners,loader liners,bucket and, teet,dampers,dredgers,crushers,grinders cyclones,pipes,deflectors,elbows,rolls,shredder knives,ash remowal systems,coal&cement transfere equipment, blast furnace bells,grizzly bars,blowers,valves etc.